How to Choose the Best Heavy Duty Cable Ties for Your Projects

When embarking on a project that requires reliable and robust fastening solutions, choosing the right heavy duty cable ties is crucial. John Smith, a recognized expert in industrial fastening solutions, emphasizes, “The right cable tie can make all the difference in ensuring safety and efficiency in your projects.” Heavy duty cable ties are not just accessories; they are essential tools that can help maintain order and organization, whether in construction, automotive, or home improvement scenarios.

The variety of heavy duty cable ties available on the market can be overwhelming. Factors like material, size, tensile strength, and temperature resistance all play a significant role in determining the ideal tie for your specific needs. According to Smith, understanding these characteristics is vital: “Investing time in selecting the right heavy duty cable tie is an investment in the success of your project.” By carefully assessing the demands of your project and the environments in which the cable ties will be utilized, you can ensure that your selection will enhance both durability and performance.

Incorporating heavy duty cable ties into your projects not only streamlines the process but also instills confidence in the integrity of your work. With the right knowledge and expert insights, you can harness the full potential of these versatile tools to achieve optimal results.

Understanding Heavy Duty Cable Ties and Their Uses

Heavy duty cable ties are essential tools in various fields, from construction and electrical work to home organization and crafting. Their primary function is to bundle and secure items tightly, providing a reliable solution for managing cables, wires, and other materials that require organization. Made from durable materials like nylon, these cable ties are designed to withstand significant weight and pressure, making them ideal for applications that demand strength and longevity.

In addition to securing cables, heavy duty cable ties have a wide range of uses. They can be employed in landscaping to bundle plants and garden supplies, in automotive settings to manage hoses and wiring, or even for creative DIY projects that require durable fastening solutions. Furthermore, their resistance to environmental factors such as moisture and extreme temperatures enhances their versatility, allowing them to perform effectively in both indoor and outdoor settings.

Choosing the right heavy duty cable ties involves considering factors like tensile strength, length, and material compatibility, ensuring that they meet the specific demands of your project.

Factors to Consider When Selecting Heavy Duty Cable Ties

When selecting heavy-duty cable ties for various projects, several critical factors must be considered to ensure optimal performance and reliability. One of the foremost considerations is the material from which the ties are made. Most heavy-duty cable ties are constructed from nylon, but variations in strength and temperature resistance can greatly affect their suitability for specific applications. According to a report by the Industrial Supply Association, nylon ties that conform to industry standards such as UL 94V-2 can withstand temperatures ranging from -40°F to 185°F, making them ideal for both indoor and outdoor use.

Another important factor is the tensile strength of the cable ties. Heavy-duty variants are designed to hold more weight without breaking. Industry standards indicate that the tensile strength of heavy-duty cable ties can vary from 50 to over 250 pounds, depending on their size and thickness. For instance, ties with larger widths and thicker materials tend to offer greater strength, making them suitable for applications involving heavy loads, such as electrical installations or automotive assembly. Additionally, considering features like UV protection and chemical resistance can be crucial for outdoor projects or environments where exposure to harsh substances is a concern. Evaluating these factors against the specific demands of your project will help in making an informed selection, ultimately enhancing the effectiveness and durability of your cable management solutions.

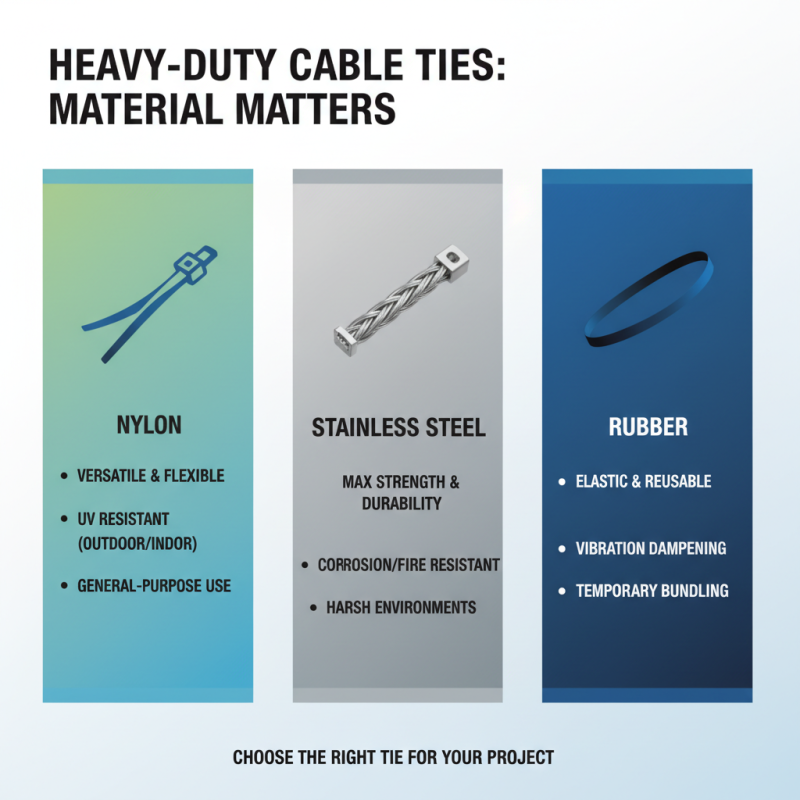

Comparing Different Materials for Heavy Duty Cable Ties

When selecting heavy-duty cable ties for various projects, understanding the differences in materials is crucial. The most common materials for heavy-duty cable ties include nylon, stainless steel, and rubber. Nylon cable ties are widely used due to their durability and flexibility, making them ideal for a range of indoor applications. They typically offer good resistance to ultraviolet (UV) light, which makes them suitable for outdoor use, although prolonged exposure can lead to degradation.

On the other hand, stainless steel cable ties provide exceptional strength and resistance to corrosion, making them a great choice for harsh environments, such as marine or industrial settings. These ties are capable of withstanding extreme temperatures and heavy loads, ensuring long-term reliability. Additionally, rubber cable ties, while less common, offer unique benefits such as stretchability and the ability to grip irregularly shaped objects securely, making them perfect for a variety of specialized tasks.

Choosing the right material is essential based on the specific requirements of your project. Consider the environment, weight capacity, and the nature of the items to be secured. By carefully comparing different materials, you can ensure that you select the most suitable heavy-duty cable tie for optimal performance and longevity.

Sizing and Strength Ratings of Heavy Duty Cable Ties

When selecting heavy-duty cable ties for your projects, understanding sizing and strength ratings is crucial to ensure you choose the right product for your needs. Heavy-duty cable ties come in various lengths, widths, and tensile strength ratings. The length is essential as it determines how much material you can bundle together, while the width affects the tie's gripping power. For example, larger bundles may require longer ties, but those ties must also be sufficiently wide to handle the load without breaking or slipping.

Tensile strength ratings, usually measured in pounds (lbs), indicate the maximum force the cable tie can withstand before failing. It is vital to consider the weight and material of the items you intend to secure. Selecting a cable tie with a strength rating that exceeds your project's requirements not only ensures safety but also provides peace of mind. Additionally, consider the environment in which the ties will be used, as factors such as temperature and exposure to chemicals can affect performance.

By prioritizing these specifications, you can effectively select the best heavy-duty cable ties suited for your specific projects.

Tips for Properly Using and Installing Heavy Duty Cable Ties

When using heavy duty cable ties, proper installation is crucial for ensuring their effectiveness and longevity. First, it’s important to select the right size and tensile strength for your specific application. Measure the bundles you're securing and choose cable ties that provide enough strength to hold the weight without breaking or slipping. Additionally, consider the environment in which the ties will be used; UV-resistant ties may be necessary for outdoor projects to prevent degradation from sunlight.

Installation technique also plays a significant role in the performance of heavy duty cable ties. Begin by threading the tail of the tie through the head, ensuring that it is secured properly. Pull the tie to tighten, but avoid over-tightening, which can lead to damage of the items being secured. For added security, especially in high-stress applications, you may consider using multiple ties spaced evenly along the bundle. Furthermore, using a cable tie installation tool can help achieve optimal tension and reduce strain on your hands, making the process easier and more efficient.

Related Posts

-

Innovative Zip Tie Tool Solutions Unveiled at the 2025 China Import and Export Fair

-

The Ultimate Guide to Choosing the Best Industrial Zip Ties for Your Projects

-

Exploring the Strength of Stainless Steel Zip Ties: The Ultimate Choice for Industrial Applications

-

Unlocking the Power of Small Zip Ties: Top 5 Insanely Useful Applications You Never Knew About

-

2025 How to Choose the Best Zip Tie Tool for Your DIY Projects

-

How to Choose the Best Long Cable Ties for Your Projects in 2025