The Ultimate Guide to Choosing the Right Metal Cable Ties for Your Project

In the realm of industrial applications and projects, the choice of fastening solutions is critical for ensuring durability and reliability. According to a recent report by the Industrial Fasteners Institute, the global market for cable ties—specifically metal cable ties—has been projected to grow at a compound annual growth rate (CAGR) of 5.7% through 2027, underscoring their vital role in various sectors, including construction, automotive, and telecommunications.

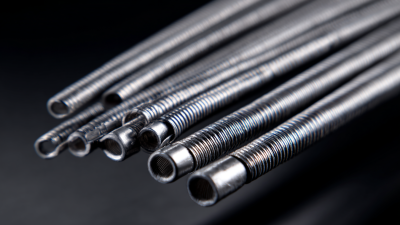

Metal cable ties are renowned for their strength, heat resistance, and ability to withstand harsh environments, making them an ideal choice for demanding applications. Additionally, a survey conducted by the International Organization for Standardization revealed that 78% of engineering professionals prefer metal cable ties over plastic options due to their superior performance in critical installations.

This guide aims to equip you with the essential knowledge to choose the right metal cable ties for your project, ensuring optimal performance and longevity.

Understanding the Different Types of Metal Cable Ties Available for Projects

When selecting metal cable ties for your project, it’s essential to understand the various types available and their specific applications. Metal cable ties, often made from stainless steel or carbon steel, are known for their durability and resistance to extreme temperatures and environmental factors. They come in different sizes and strengths, allowing you to choose the right one based on the weight and type of cables or items you need to bundle or secure.

One of the key distinctions among metal cable ties is their locking mechanism. Traditional locking ties use a one-piece design that provides a reliable hold, while ratchet-style ties allow for adjustability and ease of use. Additionally, some metal ties feature a protective coating to prevent corrosion, making them ideal for outdoor projects or environments exposed to harsh chemicals. Understanding these variations will help ensure you select the most suitable metal cable tie for your specific project needs, enhancing both safety and efficiency.

The Ultimate Guide to Choosing the Right Metal Cable Ties for Your Project

| Type of Metal Cable Tie | Material | Length (inches) | Width (inches) | Max Load (lbs) | Temperature Range (°F) | Applications |

|---|---|---|---|---|---|---|

| Standard Metal Cable Tie | Stainless Steel | 12 | 0.20 | 50 | -80 to 450 | Electrical, Construction |

| Heavy-Duty Cable Tie | Galvanized Steel | 18 | 0.30 | 100 | -40 to 400 | Industrial, Outdoor |

| Heat-Resistant Cable Tie | Stainless Steel | 24 | 0.25 | 75 | -65 to 600 | Automotive, Aerospace |

| Corrosion-Resistant Cable Tie | 304 Stainless Steel | 15 | 0.22 | 60 | -30 to 500 | Marine, Chemical |

Key Factors to Consider When Selecting Metal Cable Ties for Your Needs

When choosing the right metal cable ties for your project, several key factors should be considered to ensure optimal performance and safety. First and foremost, the tensile strength of the cable ties is crucial; it determines how much weight and pressure the ties can withstand without breaking. This is particularly important in industrial applications where heavy cables or equipment are involved. According to recent market analyses, the global cable ties market is expected to expand significantly, with a projected growth from $331.42 million in 2024 to $666.78 million by 2032, indicating increasing demand for reliable fastening solutions.

Material type is another essential aspect to consider. Metal cable ties can be made from various materials, including stainless steel and aluminum, each offering different levels of corrosion resistance and durability depending on the environment in which they will be used. For example, stainless steel ties are ideal for outdoor settings or harsh conditions where exposure to moisture and chemicals is inevitable. Additionally, the width and length of the ties should be matched to the specific application, ensuring that they offer a snug fit without the risk of damage to the cables being secured. As the market continues to grow and evolve, understanding these factors will help users make informed decisions that enhance the longevity and reliability of their projects.

Evaluating the Strength and Durability of Metal Cable Ties

When evaluating the strength and durability of metal cable ties, it's essential to consider the materials used in their construction. Most metal cable ties are made from stainless steel, which offers excellent resistance to corrosion and rust, making them ideal for both indoor and outdoor applications. The gauge of the metal also plays a critical role in their strength, with thicker gauges providing increased tensile strength for heavy-duty tasks. Users should assess the specific environmental conditions their projects may encounter, as exposure to harsh chemicals or extreme temperatures can affect the performance of the ties.

In addition to material and gauge, the design features of metal cable ties contribute significantly to their durability. Look for ties that have a locking mechanism that provides a secure closure without risk of loosening over time. Some manufacturers offer cable ties with additional features, such as UV resistance or enhanced flexibility, which can ensure a longer service life in challenging conditions. Evaluating these factors will help you choose the right metal cable ties that deliver both the strength required for your project and the durability necessary to withstand the test of time.

The Strength and Durability of Metal Cable Ties

This chart illustrates the tensile strength and temperature resistance of various metal cable ties, helping you choose the right one for your project.

How to Choose the Right Size and Length of Metal Cable Ties

When selecting metal cable ties for your project, determining the right size and length is crucial for ensuring optimal performance and reliability. Begin by assessing the items you need to bundle. The width and thickness of the items will guide you in choosing a tie that can securely hold them together without risking breakage or slippage. Generally, wider ties provide greater strength, making them ideal for heavier items or large bundles of cables, while narrower options may suffice for lighter applications.

In terms of length, it's important to consider the total circumference of the bundle you'll be securing. When in doubt, opt for a longer tie, as they can be easily trimmed to the desired length. A good rule of thumb is to choose a tie that is at least 4 inches longer than the circumference of the bundle for adequate overlap and securing. Additionally, keep in mind that some tasks may require ties with adjustable or unique designs, so reviewing your project specifications can further guide your selection process. By carefully evaluating the size and length, you'll ensure that your metal cable ties provide the necessary support and stability for your specific needs.

Tips for Proper Installation and Use of Metal Cable Ties in Various Applications

When selecting metal cable ties for various applications, it's essential to understand the specific requirements of your project. Metal cable ties are available in both metallic and non-metallic types, each serving distinct functions. According to recent market analysis reports, the demand for metallic cable ties is growing due to their durability and strength, making them ideal for heavy-duty environments where robustness is critical. These ties can withstand extreme temperatures and exposure to harsh chemicals, making them the preferred choice in industries such as construction and automotive.

For proper installation and use, consider these tips: First, ensure that the metal cable tie is compatible with the materials it will secure. The width and thickness of the tie should be appropriate for the cable bundle to avoid damage. Second, utilize the correct installation techniques; a taught tie can prevent cable movement, reducing wear and tear over time. Lastly, always check local regulations, as some applications may require ties that meet specific industry standards.

In addition to installation tips, stay updated on new products like the Power-Tie designed for solar projects, combining the durability of metal with user-friendly features. Understanding these advancements can give you an edge in your project planning and execution, ensuring you select the best metal cable ties for your unique application.

Related Posts

-

Exploring the Impact of Zip Tie Tool Innovations at the 2025 China 138th Export Commodities Fair

-

Why Releasable Cable Ties Are a Game Changer for Your Organization

-

15 Essential Tips for Using Stainless Cable Ties Effectively

-

How to Choose the Right Plastic Ties for Maximum Strength and Durability

-

Mastering the Versatility of Nylon Cable Ties: Innovative Uses You Never Knew Existed

-

Innovative Zip Tie Tool Solutions Unveiled at the 2025 China Import and Export Fair