How to Use Steel Zip Ties for Strong and Durable Connections?

Steel zip ties have become essential tools in various industries, known for their strength and durability. According to a report by the Industrial Fasteners Institute, these fastening solutions can handle loads up to 175 pounds or more. This impressive capacity makes them ideal for heavy-duty applications in construction and automotive sectors.

In applications like these, the ability to securely bundle cables or hold materials together is crucial. Steel zip ties outperform their plastic counterparts, especially in extreme environments. They are resistant to UV degradation, temperature fluctuations, and chemicals. A surprising statistic is that about 30% of professionals encounter failures with plastic ties in demanding situations. This raises doubts about efficiency and safety.

Despite their advantages, improper use of steel zip ties can lead to issues. Over-tightening can damage sensitive materials, while under-tightening may cause failures. Awareness of best practices is vital for maximizing their effectiveness. Incorporating steel zip ties in your toolkit could be a game-changer, yet assessing their risks is equally important.

Understanding the Basics of Steel Zip Ties and Their Applications

Steel zip ties are increasingly popular in various industries. Made from stainless steel, they offer strong and durable connections. Unlike plastic ties, they resist heat, cold, and corrosion. This makes them ideal for challenging environments, like construction sites or manufacturing plants.

A recent industry report highlights that over 60% of professionals prefer steel zip ties for securing heavy loads. They provide higher tensile strength compared to traditional plastic options. In fact, many steel ties can withstand hundreds of pounds of pressure. This reliability makes them essential for safety-critical applications.

However, users need to be cautious. Improper installation can lead to failure. It's crucial to choose the right gauge for your needs. A thick tie offers strength but can be harder to work with. Sometimes, this may cause frustrations and lead to poor connections. Proper training in using these ties may reduce mistakes.

Choosing the Right Type of Steel Zip Tie for Your Project

When choosing the right type of steel zip tie for your project, consider several factors. Different tasks require different strengths. The tensile strength is crucial. For heavy-duty applications, select ties with higher tensile ratings. Light-duty ties may suffice for basic needs.

Material matters. Stainless steel ties resist corrosion and are ideal for outdoor use. Coated options can add extra protection. Think about the environmental conditions. Will they face extreme temperatures? Choose accordingly.

**Tips:** Check the length and width. Ensure they fit your items snugly. A tie that’s too loose can fail under pressure. Also, think about installation ease. Some designs require special tools. Others are user-friendly. Handling is key.

Placement is another consideration. Avoid sharp edges that can damage ties. Inspect them regularly for wear and tear. Even durable ties can degrade over time. Reflect on your project’s demands and adjust your choices. It's an ongoing process.

How to Use Steel Zip Ties for Strong and Durable Connections

| Type of Steel Zip Tie | Strength (lbs) | Length (inches) | Width (mm) | Temperature Resistance (°F) |

|---|---|---|---|---|

| Standard Steel Zip Tie | 200 | 14 | 7.6 | 150 |

| Heavy-Duty Steel Zip Tie | 300 | 18 | 9.0 | 200 |

| Releasable Steel Zip Tie | 150 | 10 | 5.0 | 175 |

| Mini Steel Zip Tie | 100 | 8 | 3.6 | 120 |

Step-by-Step Guide to Properly Secure Connections with Steel Zip Ties

Zip ties are a popular choice for securing items due to their strength and durability. Steel zip ties stand out in this category as they offer exceptional resistance to environmental elements. When using steel zip ties, proper installation ensures safety and reliability. According to industry studies, stainless steel offers a tensile strength of up to 200 PSI, making them ideal for heavy-duty applications.

Begin by selecting the right size of zip tie. Length and width play a crucial role in the strength of the connection. Small zip ties may not handle heavy loads and could snap under pressure. When securing wires or materials, thread the tie through the locking mechanism clearly. An improper lock can weaken the connection, causing potential hazards. Secure tightly, but do not overtighten, as this can damage the secured items.

When in harsh environments, consider the corrosion resistance of the steel. Stainless steel is preferable for outdoor projects. Remember, even the best materials can fail without proper handling. Regular inspections of secured connections can prevent failures. Adjustments may be necessary if rust or wear appears early. Incorporating these practices ensures reliable use of steel zip ties for any project.

Best Practices for Installation and Maintenance of Steel Zip Ties

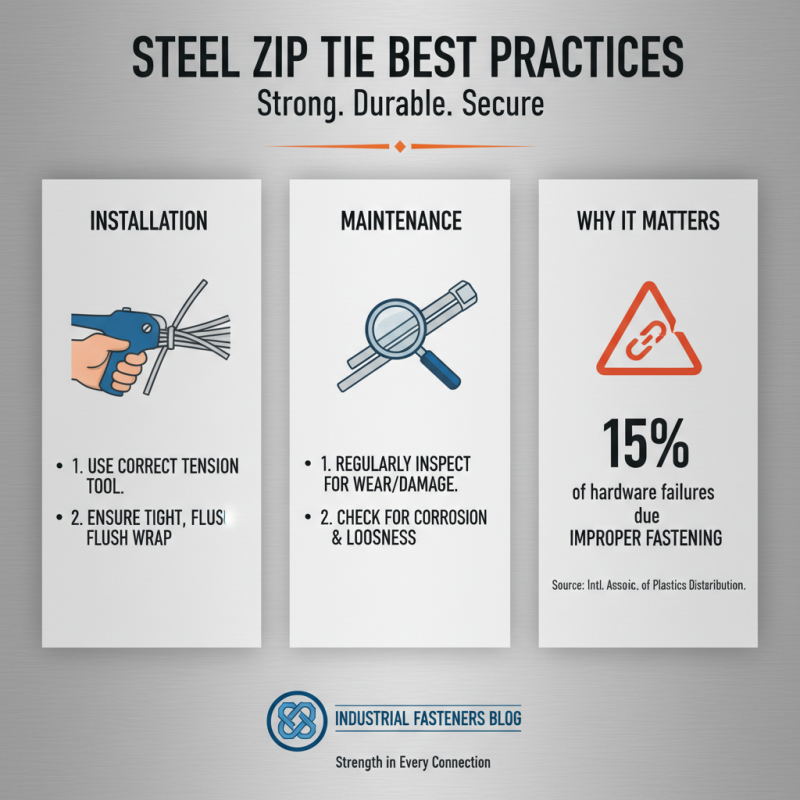

When using steel zip ties, proper installation and maintenance are critical for ensuring strong and durable connections. According to a report by the International Association of Plastics Distribution, approximately 15% of hardware failures are linked to improper fastening techniques. This statistic highlights the importance of understanding best practices with steel zip ties, which are known for their strength and resilience.

Firstly, ensure that the surface is clean and free of debris. Dirt can weaken the bond and reduce the lifespan of the tie. After installation, inspect the ties regularly for signs of wear or corrosion. Corrosion can significantly weaken the integrity of the connection. The American Society for Testing and Materials states that maintenance neglect can lead to failures in up to 20% of industrial applications.

It's essential to select the appropriate size for the specific task. Using a steel zip tie that is too small may lead to over-tensioning, resulting in potential failure. Conversely, excessively large ties can create slack, reducing stability. The key is a snug fit without compromising the integrity of the materials being connected. Regular assessments of the ties’ performance can help identify weaknesses before they result in costly repairs.

Safety Considerations When Using Steel Zip Ties for Strong Connections

When using steel zip ties, safety is crucial. Their strength can be deceptive. Without care, they can cause injuries. Always wear gloves to protect your hands. Sharp edges can cut skin. Tightening them too much can lead to unexpected issues. Monitor yourself when using them.

Ensure that you use the right tie for the job. Too small may snap, while too large may not hold effectively. Check weight limits on various zip ties. Always inspect the ties before use. A slight flaw can lead to a catastrophic failure. It’s best to err on the side of caution.

While steel zip ties offer durability, their misuse can result in accidents. Always consider surrounding materials before application. Nearby wires or delicate surfaces can be damaged. Reflect on past experiences to avoid mistakes.

Safety in using steel zip ties is about awareness and smart choices.

Related Posts

-

10 Best Steel Zip Ties for Maximum Durability and Versatility in Securing Cables

-

Ultimate Guide to Heavy Duty Zip Ties Tips for Maximum Strength and Durability

-

The Ultimate Guide to Using Long Zip Ties for Home Organization and DIY Projects

-

Top Uses for Zip Ties in Everyday Life and DIY Projects?

-

Unlocking the Power of Small Zip Ties: Top 5 Insanely Useful Applications You Never Knew About

-

2025 How to Choose the Best Zip Tie Tool for Your DIY Projects